Thermal Balance

Stash Hockey is pleased that its range of garments includes items that help maintain your body temperature and ensure you remain comfortable. To help achieve this the fabric wicks moisture away from the skin efficiently by evaporation, this helps regulate body temperature. Therefore help in keeping you warm when the weather is cold and keeping you cool in the heat. This helps to improve performance and recovery.

Water Repellent

Stash Hockey know that you train in all weather conditions and water repellence is a key feature. The outer shell of the garment is a barrier to rainwater preventing it from penetrating the fabric surface, increasing the time before the garment “wet out” allowing the wearer to stay drier and more comfortable for longer.

Access Zip

At Stash Hockey we know how important it is to add embellishment to the garments, the easy access zip is ideal for club badges, logo’s and numbers.

Waterproof Breathable

Stash Hockey have worked closely with our factories to ensure the highest levels of performance of our fabrics and in turn the garments. A Microporous PU coaching on the reverse of the outer shell allows moisture vapour to pass easily from the inside of the garment through to the outside whilst preventing rain water from penetrating the fabric, enhancing levels of comfort.

Easy Care

Stash Hockey, understand the requirements that Hockey players need and how important it is that your kit is easy care. All our fabrics are fit for purpose, but not at the expense of specialist care instructions - all fabrics can be machined washed on a regular basis.

Wind resistant

Stash Hockey know you will be exposed to every type of weather that the British climate can throw at you and wind will certainly be one of them. 2 and 3 layer fabrics specifically designed to be weather proof, keeping you warm when you need it most.

Taped Seams

Stash Hockey understand the demands the garments will be put through and it is critical that to further enhance the performance of the waterproof fabric, high frequency welded tapes are applied to the inside of the seams of the garments.

Quick Dry

Stash Hockey are out on the turf 7 days a week and we know that as well as all the performance aspects that the fabric and garments have to go through that quick drying is key. An additional process is applied to the fabric during dying which allows the fabric to evaporate moisture away from the skin keeping you warm and dry. This also helps a quick turnaround time after washing.

Fit for Purpose

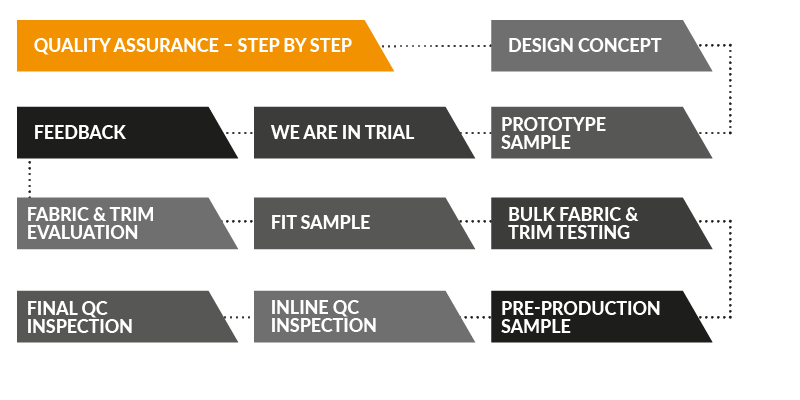

All too often, many less experienced manufacturers and importers overlook the importance of controlling garment quality to the necessary level at key production stages, whether it be technical fabric performance, stitching or the durability of a critical trim. Proven quality procedure is integral to manufacturing suitable garments which fit and function according to their intended use, giving the buyer confidence in the product.

Designed and developed in the UK, this range is manufactured by hand-picked specialist partners and quality is rigorously controlled at all stages. The highly detailed specifications of the garments pay particular attention to reinforcing them in the right places and specifying the most suitable fabrics to reduce the risk of unwanted returns.

Whilst all the approved factories have in-house quality procedures to international standards, the quality assurance team for these products is not employed by the manufacturer. They are dedicated and experienced full-time staff working exclusively on this range, trained to understand the small but important details that make the difference in a garment.

Manufacturers are chosen on their proven ability to produce specific product types, which enables them to offer valuable input when developing new products.

To give you an idea why these products are genuinely “fit for purpose” please study the step-by-step quality assurance flow chart, which highlights the rigorous procedure undertaken to control quality at every stage.

Standards

Oekotex Standard 100

The Oekotex standard is an independent, international testing and certification system for textile raw materials. Intermediate and end textile products at all stages of production – such as yarns, raw and dyed fabrics and knits, ready made clothing, domestic textiles.

CRITERIA

Testing for harmful substances includes:

Illegal substances

Legally regulated substances

Known harmful chemicals (unregulated)

Parameters of healthcare

In their entirety, the overall requirements of Oekotex exceed existing legislation. The Oekotex criteria helps highlight the additional benefits of safety tested textiles. Please note that not all trims and components in these garments carry the Oekotex standard. However any such trims and components are tested in accordance with Oekotex whenever possible as part of an ongoing commitment to improving both environmental and ethical practices throughout the supply chain.

ITS INTERTEK

In a competitive garment industry full of complex regulations, it is imperative for manufacturers, retailers, importers and distributors to proactively evaluate fabrics and trims to ensure they are producing the highest quality apparel, from the first stitch, for demanding consumers. By ensuring fabric quality from the start, the result is more durable apparel that stands the test of time. The fabric and trims utilised in this range are tested exclusively by Intertek to international standards.

Intertek is a leading quality solutions provider to industries worldwide. From auditing and inspection, to testing, training, advisory, quality assurance and certification, Intertek adds value for its customers by helping improve the quality and safety of their products, assets and processes. With a network of more than 1,000 laboratories and offices and over 38,000 people in more than 100 countries. Intertek supports companies’ success in the global marketplace by helping customers to meet end user’s expectations for safety, sustainability, performance, integrity and desirability in virtually any market worldwide. For more information, visit www.intertek.com

Some of the essential tests Intertek performs on fabric include the following

Staining – colourfastness to washing

Tear Strength

Pilling / Snagging resistance

Wet/dry rub fastness

Dimensional stability (Shrinking to washing)

Spirality

Seam Strength

Stretch and Recovery

Ethical and Social Responsibilities

All manufacturers associated with the production of these products subscribe to a range of recognised ethical trading initiatives such as burea veritas BSCI (Business social compliance initiative) or sedex (supplier ethical data exchange ) and recognise their social and corporate responsibilities to their employees, buyers and end users. Garments are produced and delivered under conditions that do not abuse or exploit any persons or environment.

These considerations form part of any evaluation and selection criteria for this range. In order to support and maintain such responsibilities, all manufacturers and visited on a regular basis. This also helps ensure that all employers within the factories are able to meet the key principals relating to working hours, forced labour and overall working environment, including accommodation.

“Independently tested to recognised international Standards”